Kverneland Exacta TLX GEOSPREAD

Aplikace velkých dávek hnojiva při vysoké rychlosti.

Hlavní výhody

- Vysokorychlostní rozmetací systém CentreFlow

- Systém rozmetání s unikátním referenčním snímačem

- Prevence překrývání se systémem GEOSPREAD

- MULTIRATE: více druhů rozmetání v rámci jedné pracovní šířky

Popis

Vysokorychlostní rozmetání

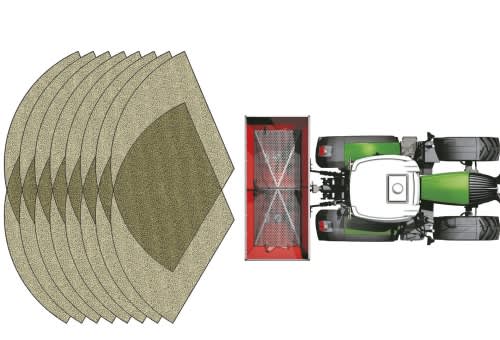

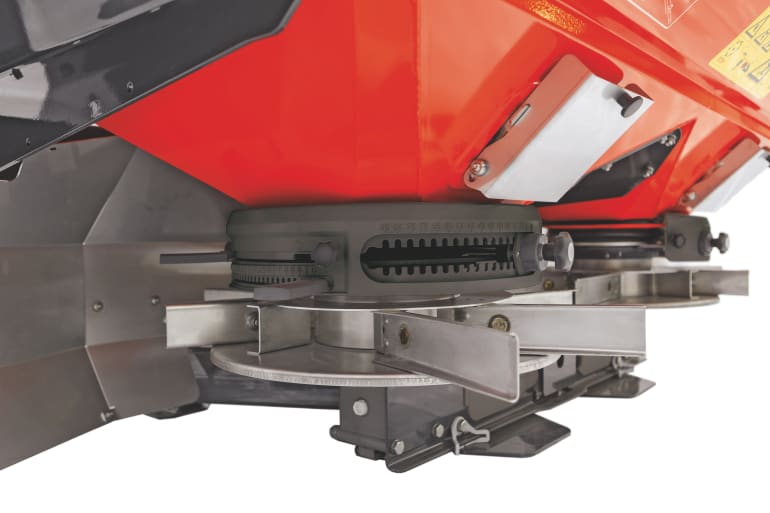

Rozmetadlo Kverneland Exacta TLX GEOSPREAD má téměř stejné parametry jako rozmetadlo Exacta TL GEOSPREAD, ale je vybaveno nově navrženým systémem CentreFlow s 8 kapacitními lopatkami na každém kotouči pro dokonalé překrytí bez ohledu na rychlost jízdy. Díky metrovým sekcím, čtyřem snímačům zatížení a referenčnímu senzoru zvládne Kverneland Exacta TLX GEOSPREAD vysokorychlostní rozmetání za všech okolností. Toto rozmetadlo je kompatibilní se sběrnicí ISOBUS a má certifikát AEF. Rozmetadlo můžete provozovat v kombinaci s traktorovým terminálem IsoMatch Tellus PRO, IsoMatch Tellus GO+ nebo jakýmkoli jiným terminálem kompatibilním s ISOBUS.

Vlastnosti

Vlastnosti

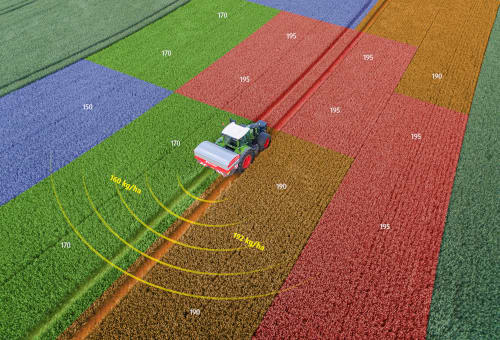

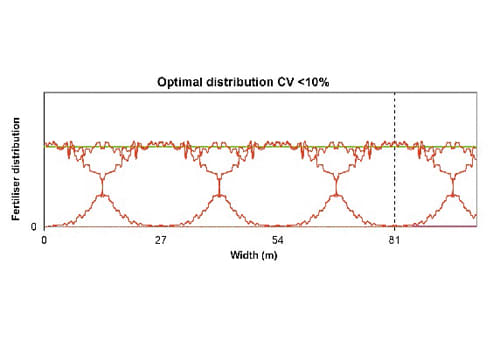

Při spuštění programu IsoMatch GEOCONTROL navíc k programu GEOSPREAD můžete přesněji nastavit programy Exacta CL, TL a TLX GEOSPREAD. Pracovní šířka se automaticky upraví tak, aby odpovídala překryvu a pokrytí pomocí polohového systému GPS. Například při jízdě na klínovitém poli nebo na poli nepravidelného tvaru začne GEOSPREAD postupně zmenšovat pracovní záběr. GEOSPREAD využívá funkci řízení sekcí softwaru IsoMatch GEOCONTROL, který je v terminálu IsoMatch Tellus PRO nebo IsoMatch Tellus GO+. Pracovní záběr rozmetadla je rozdělen na sekce o minimální délce 1 metr (max. 45 sekcí u modelu TLX GEOSPREAD, max. 54 sekcí u TL GEOSPREAD a max. 33 sekcí u CL GEOSPREAD). Upravuje se záběr rozmetání a analogicky aplikační dávka (kg/min). Díky této jedinečné kombinaci nastavení pracovního záběru a aplikační dávky je systém GEOSPREAD mimořádně přesný, s minimálním vlivem na variační koeficient rozmetacího obrazce.

VÝHODY

- Rychlé a přesné rozmetání díky variabilitě ovladačů. Žádné spoje.

- Stabilní otáčky kotoučů zachovávají obrazec rozmetání (koeficient změny).

- Řízení sekcí s 1metrovými úseky (v závislosti na funkčnosti terminálu).

- Jednoduché ovládání; pro nastavení pracovního šířky není nutné vystupovat z traktoru.

- 100% kompatibilita s ISOBUS pro jednoduché ovládání.

- S GPS možnost automatického spuštění/zastavení na souvratích.

Aplikace AutosetApp umožňuje mít vždy k dispozici nejaktuálnější nastavení vašeho rozmetadla. AutosetApp je softwarová aplikace dostupná na terminálu IsoMatch Tellus PRO nebo IsoMatch Tellus GO+. Aplikace AutosetApp je standardně integrována do softwaru IsoMatch GEOCONTROL. Tato aplikace propojuje terminál přímo s rozmetadlem GEOSPREAD a automaticky nastavuje rozmetadlo podle požadavků zadaných do aplikace. Aplikace AutosetApp bude fungovat také v kombinaci s CL-EW a TL, s tím, že u těchto rozmetadel je třeba bod vypouštění (nastavení písmene) ještě nastavit ručně na samotném rozmetadle.

Databáze rozmetadel hnojiv Kverneland s nejaktuálnějšími grafy rozmetání je vždy k dispozici online. Aplikace AutosetApp se může připojit k databázi rozmetadel hnojiv dvěma různými způsoby. Můžete ji připojit k online databázi prostřednictvím USB adaptéru IsoMatch Wireless WIFI nebo si stáhnout nejaktuálnější databázi z webových stránek www.kvernelandspreadingcharts.com na USB flash disk a nahrát databázi přímo do terminálu IsoMatch Tellus PRO nebo IsoMatch Tellus GO+.

Pro snadné a nákladově efektivní rozmetání

MULTIRATE (aplikace s proměnlivou dávkou) aplikuje více dávek v rámci pracovní šířky.

Aby bylo možné rozmetat správné množství hnojiva na konkrétní místo na poli, je třeba mít v rámci pracovní šířky různou dávku. V závislosti na variabilitě pole a velikosti rastru mapy variabilní aplikace lze použít zadání 2, 4, 6 nebo 8 úseků dávky. To znamená přesnější dávkování hnojiv, které umožní lepší účinnost živin, vyšší výnosy a snížení nákladů.

S rozmetadlem Kverneland GEOSPREAD investujete do 100% kompatibility se sběrnicí ISOBUS pro snadné zapojení a provoz s terminálem IsoMatch Tellus PRO nebo jakýmkoli jiným terminálem certifikovaným AEF. V několika krocích s touto kombinací jste připraveni používat aplikaci MULTIRATE. Musíte převést satelitní nebo pozemkovou mapu do souboru ISO-XML. Stáhněte si variabilní aplikační mapy do terminálu a můžete rozmetat pomocí aplikace MULTIRATE se 2 až 8 dávkami.

Zvýšení kapacity

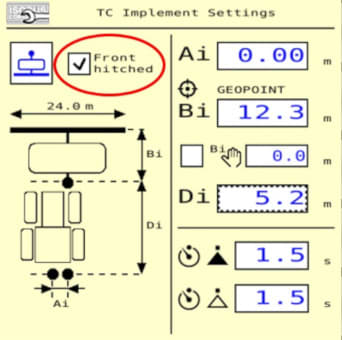

Kombinace předního a zadního rozmetacího zařízení nejenže zvýší celkovou kapacitu zásobníku až na 6 000 nebo 7 000 l, ale také umožňuje rozmetat dvě různé aplikace při jednom přejezdu. To šetří čas a práci díky menšímu počtu přejezdů a také snižuje poškození půdy.

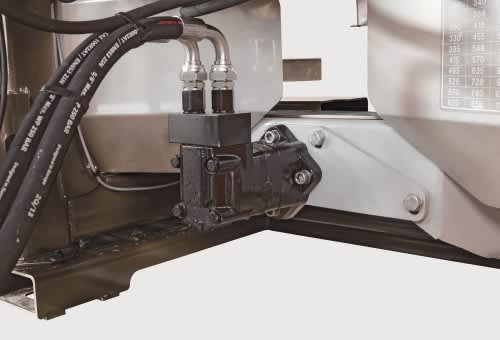

S jedním menším rozmetadlem vpředu a druhým vzadu se perfektně vyvážení hmotnost traktoru, což znamená zmenšení tlaku na půdu a jejího zhutnění, což může být užitečné zejména ve vlhkých podmínkách. V případě, že v přední části traktoru není k dispozici vývodová hřídel, lze u rozmetadel GEOSPREAD použít centrální hydraulický pohon.

Díky sadě předního osvětlení, která je k dispozici jako volitelná výbava, se při umístění rozmetadla v přední části traktoru zapne osvětlení vozovky ve správném směru jízdy.

Precizní způsob rozptylu

Rozmetání dvou různých hnojiv najednou při jednom přejezdu zvýší správnost výživy. Dva různé typy hnojiv s různými fyzikálními vlastnostmi lze aplikovat se správným nastavením, aby byl zajištěn dokonalý způsob rozmetání. Výsledkem je zvýšení výnosu a úspora nákladů na hnojiva.

Nejrůznější kombinace

Všechny modely rozmetadel Kverneland, i s různým objemem zásobníku, lze kombinovat vpředu i vzadu. U modelů, kde není k dispozici okrajové zařízení ExactLine pro rozmetání na levé straně, však dochází k omezení rozmetání okrajů na souvrati. V Task Control (TC) na terminálu ISOBUS je možnost zvolit přední rozmetadlo a zadat správné nastavení pro přední rozmetadlo.

Zvýšení efektivity

Díky kombinaci předního a zadního rozmetadla a dvěma připojeným terminálům ISOBUS je možné ušetřit mnohem více nákladů a zvýšit efektivitu! Aby se minimalizovalo překrývání, sekční řízení automaticky zapíná a vypíná sekce na obou rozmetadlech. Díky variabilnímu dávkování u všech rozmetadel Kverneland GEOSPREAD je možné automaticky nastavit dávku zvlášť z předního a zadního rozmetadla. Pro ještě větší přesnost aplikuje systém MULTIRATE více dávek v rámci pracovní šířky nezávisle na předním a zadním rozmetadle.

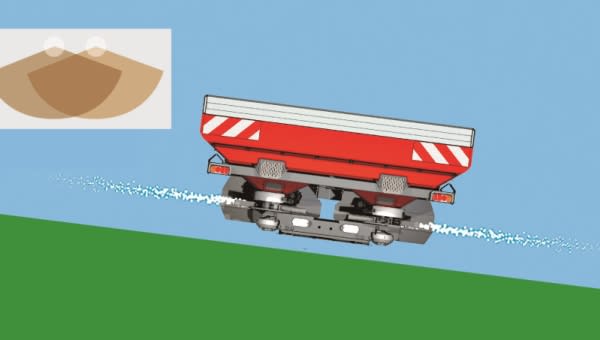

Vysoce kvalitní lopatky jsou nejlepší volbou pro maximální výkon.

Zvýšené používání velmi tvrdých hnojiv s ostrými hranami při vysokém průtoku zkrátí životnost lopatek. Opotřebované lopatky vytvářejí nepravidelný rozptylový vzor, což způsobuje nerovnoměrné rozložení živin a potenciální ztrátu úrody.

Rozmetací lopatky XHD odolné proti opotřebení jsou zárukou dlouhé životnosti a spolehlivosti stroje. Pro tento účel byla zavedena povrchová úprava uhlových lopatek.

Rozmetací lopatky XHD jsou vyrobeny ze standardní nerezové oceli Duplex, ošetřené vrstvou karbidu chromu pro zvýšení jejich odolnosti proti opotřebení. Karbid chromu je extrémně tvrdý a korozi odolný materiál. Je zahřátý na velmi vysoké teploty a nastříkán na lopatku, aby se vytvořila ochranná vrstva. Karbid chromu zvyšuje odolnost proti opotřebení, ale nemá žádný vliv na rozmetací vzor. Rozmetací lopatky XHD poskytují zemědělcům vysoce kvalitní vzor rozmetání a dlouhou životnost.

- Bez nárazů, bez rozdrobení, bez prachu: Hnojivo se dostane na rychlost kotoučů ještě předtím, než dosáhne lopatky.

- Přesné rozmetání: Dvojité překrytí rozmetacího diagramu zajišťuje bezkonkurenční přesnost. Osm lopatek na každém kotouči zajišťuje plynulý tok hnojiva na pole. To je důležité pro vysoký výkon rozmetání a pojezdovou rychlost.

- Minimální vliv větru, maximální přesnost: Ploché kotouče a vodorovný tok hnojiva poskytují symetrický obrazec rozmetání. Osm lopatek na kotouč, osm sektorů na otáčku zajišťuje rovnoměrnost rozmetání s dvojitým překrytím.

- Zaručená přesnost na svazích: Hnojivo se dotýká lopatek vždy ve stejném bodě, a to i na svazích, a pohybuje se po celé délce lopatek.

- Průběžná dynamická "online - kalibrace" s vysokofrekvenčním komunikačním signálem.

- Jedinečná technologie referenčního snímače Kverneland: všechny negativní vlivy jsou automaticky korigovány a eliminovány, což zajišťuje maximální přesnost rozmetání i v kopcovitém terénu. Referenční snímač Kverneland vám poskytuje absolutní přesnost, protože každý kilogram se počítá!

- Váhové snímače v kombinaci s unikátním referenčním snímačem:

- Automatická kalibrace a kontinuální systém vážení

- Automatická korekce na svazích

- Automatická korekce otřesů i na nerovném terénu

- Automatický systémdávkování v závislosti na rychlosti

- Není nutný kalibrační test

- Nejvyšší přesnost za všech podmínek: zaručena rovnoměrná jakost rozmetání! Ušetřete náklady a zvyšte kvalitu!

- Kompaktní "přístrojová deska" EasySet umožňuje výrazně zjednodušené přesné nastavení a úpravu aplikačních dávek. Dvě hydraulicky ovládaná dávkovací šoupata, každé se třemi výsypnými otvory, zajišťují rovnoměrný tok hnojiva ze zásobníku k rozmetacím kotoučům.

- Vývojové oddělení výzkumného a vývojového týmu rozmetadel Kverneland má vlastní kompetenční centrum rozmetadel, aby bylo možné provádět průběžné testování po celý rok. Všechny testy jsou prováděny podle nejpřísnějších mezinárodních norem a požadavků na kvalitu.

- Klíčem k přesnému rozmetání je co nejpřesnější sladění kvalitativních parametrů hnojiva a jeho litrové hmotnosti s rozmetacími tabulkami. Kontrolní seznam Kverneland Exacta vám pomůže zajistit konzistentní přesnost za všech polních podmínek.

- Zvolte typ hnojiva

- Určete velikost a rozložení granulí

- Určete litrovou hmotnost

- Přímý přístup k nejnovějším výsledkům testů na adrese: www.kvernelandspreadingcharts.com nebo si stáhněte aplikaci spreading charts v App Store nebo ji získejte na Google Play.

- Společnost Kverneland nabízí systém ExactLine nebo manuální/hydraulicky ovládaný deflektor pro rozmetání na okrajích pole. Systém ExactLine lze přesně nastavit pro všechny typy hnojiv a pro všechny pracovní záběry. Obsluha je jednoduchá, není třeba opouštět sedadlo traktoru. U modelů HL, TL a TLX lze systém ExactLine namontovat dokonce na levou i pravou stranu rozmetadla.

- Při jednostranném okrajovém rozmetání se traktor pohybuje přibližně 2 metry od hranice pole.

- Při rozmetání na mezní pásy jede traktor v první stopě a rozmetá k hranici pole. Vzdálenost k hranici je polovina pracovního záběru.

- Indikátor hraničního rozmetání (BSI), indikuje, které zařízení na hraniční rozmetání je aktivní.

- Rozmetadla Exacta HL/TL(X) jsou k dispozici také namontovaná na přívěsném rámu.

- Centrální hydraulický pohon jako volitelná výbava je k dispozici pro HL/TL(GEOSPREAD).

- Pro zvýšení kapacity zásobníku jsou k dispozici snadno sestavitelné hliníkové nástavce zásobníku.

- Jako volitelné příslušenství je k dispozici snadno sklopný kryt zásobníku. Jednoduchá montáž! Může se jednat o manuální kryt zásobníku nebo o elektrickou verzi ovládanou přes kabinu traktoru.

- Volitelně je k dispozici levý/pravý uzavírací ventil pro rozmetání při poloviční pracovní šířce.

- Pro zajištění konzistentního průtoku při rozmetání malého množství nebo rozmetání semen a granulí proti slimákům je systém CentreFlow vybaven sadou pro jemnou aplikaci.

- Standardní výbavou rozmetadla Exacta CL jsou robustní mřížky ve tvaru delty.

- Středová převodovka se dvěma vstupními hřídeli pro nastavení vysokých a nízkých otáček kotoučů je standardní výbavou rozmetadla HL/TL(X).

- Sada pro vyprazdňování zásobníku je volitelně k dispozici pro snadné vysypání zbývajícího hnojiva ze zásobníku.

- Snadná kalibrace se provádí pomocí volitelné kalibrační nádoby.

- Sada LED osvětlení s dlouhou životností je volitelnou výbavou pro rozmetadla EL, CL a CL-EW. Pro HL, TL a TL(X) je tímto standardním vybavením rozmetadlo GEOSPREAD.

- Ochranné kryty proti blátu (volitelná výbava) chrání rozmetací kotouče před blátem, vodou apod.

Technické údaje

Technické údaje

Stáhnout prospektExacta TLX GEOSPREAD |

TLX GEOSPREAD 1875 |

TLX GEOSPREAD 2550 |

TLX GEOSPREAD 3225 |

TLX GEOSPREAD 3900 |

Objem zásobníku (l) |

1875 |

2550 |

3225 |

3900 |

Plnící výška |

123 |

142 |

161 |

180 |

Šířka (cm) |

290 |

|||

Plnící šířka (cm) |

284 |

|||

Hmotnost (kg) |

705 |

735 |

765 |

796 |

Pracovní záběr (m) |

24 - 45* |

|||

Průtok hnojiva (kg/min) |

10 - 540 |

|||